Well, let me tell you, making refractory bricks ain’t as simple as it sounds, but it’s somethin’ that’s been done for ages. Now, these bricks are the ones that can stand up to high heat without crumblin’. You might see ’em in kilns, ovens, and even chimneys. They ain’t the same as regular bricks, no sir. These special bricks gotta handle fire and high temperatures without breakin’ down, so they’re made from some mighty tough stuff.

First thing’s first, you gotta pick the right materials.

The main ingredients in these here bricks are usually things like fireclays, which are a kind of clay that’s got aluminum in it. You also got yourself minerals that have high aluminum oxide content, like bauxite and diaspore. Then there’s the sand and quartzite, which have silica in ‘em. And don’t forget about magnesia minerals, like magnesite and dolomite—these are also important for makin’ strong bricks. Some folks even use chromite, which comes from iron ore and chromium. All these materials work together to make sure the brick won’t melt or break apart when it’s sittin’ in a hot kiln.

Once you got your materials, it’s time for the mixin’!

You mix all these ingredients together with a little bit of water to make a paste, sort of like making bread dough, only a lot more fire-resistant. You also might add some sodium silicate, which is a fancy way of sayin’ “water glass.” This stuff works like a glue, holdin’ everything together once it hardens. Now, when I first started making these bricks, I just used sand, perlite, and sodium silicate. It’s a good ol’ simple mix, but it sure did the job!

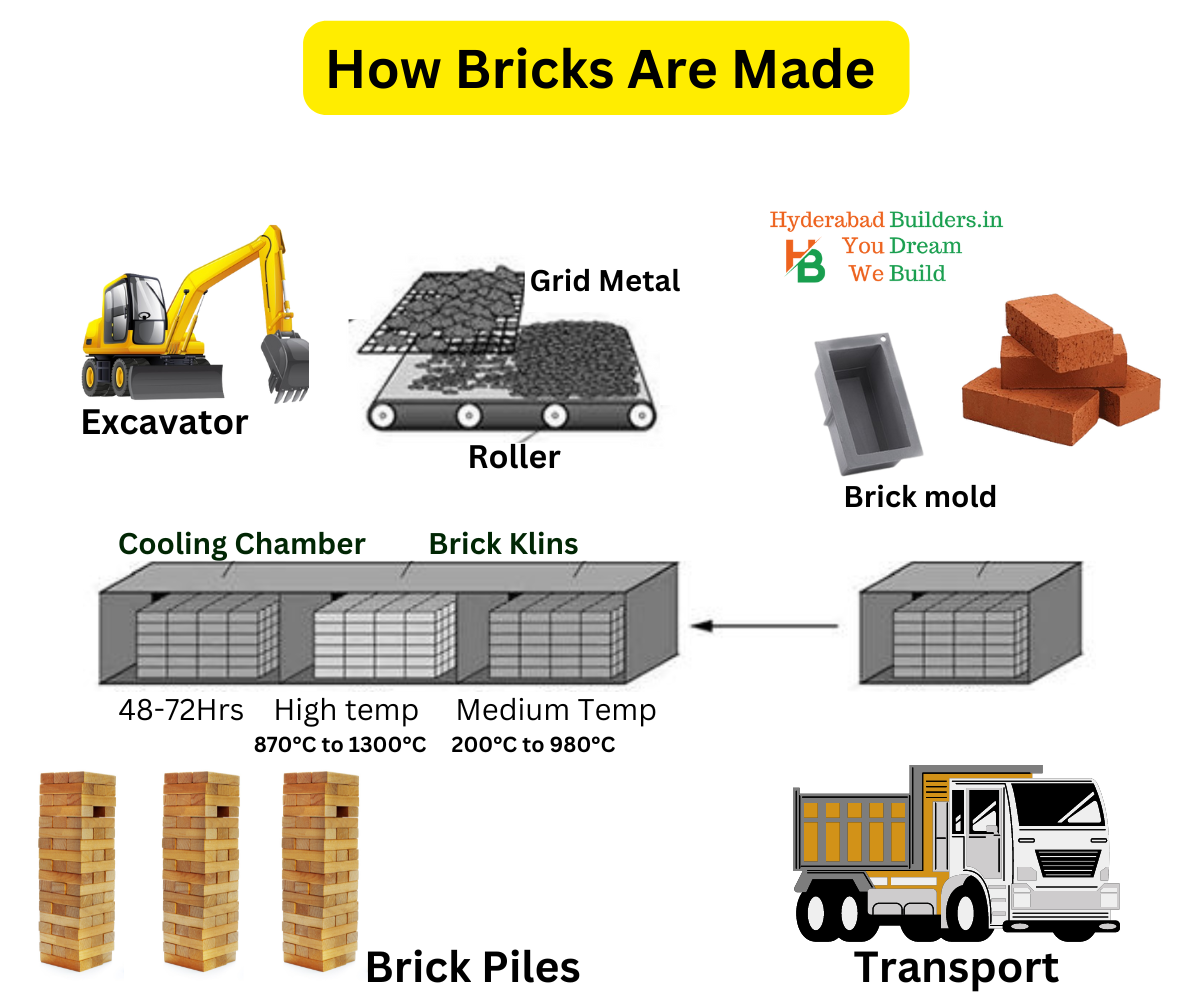

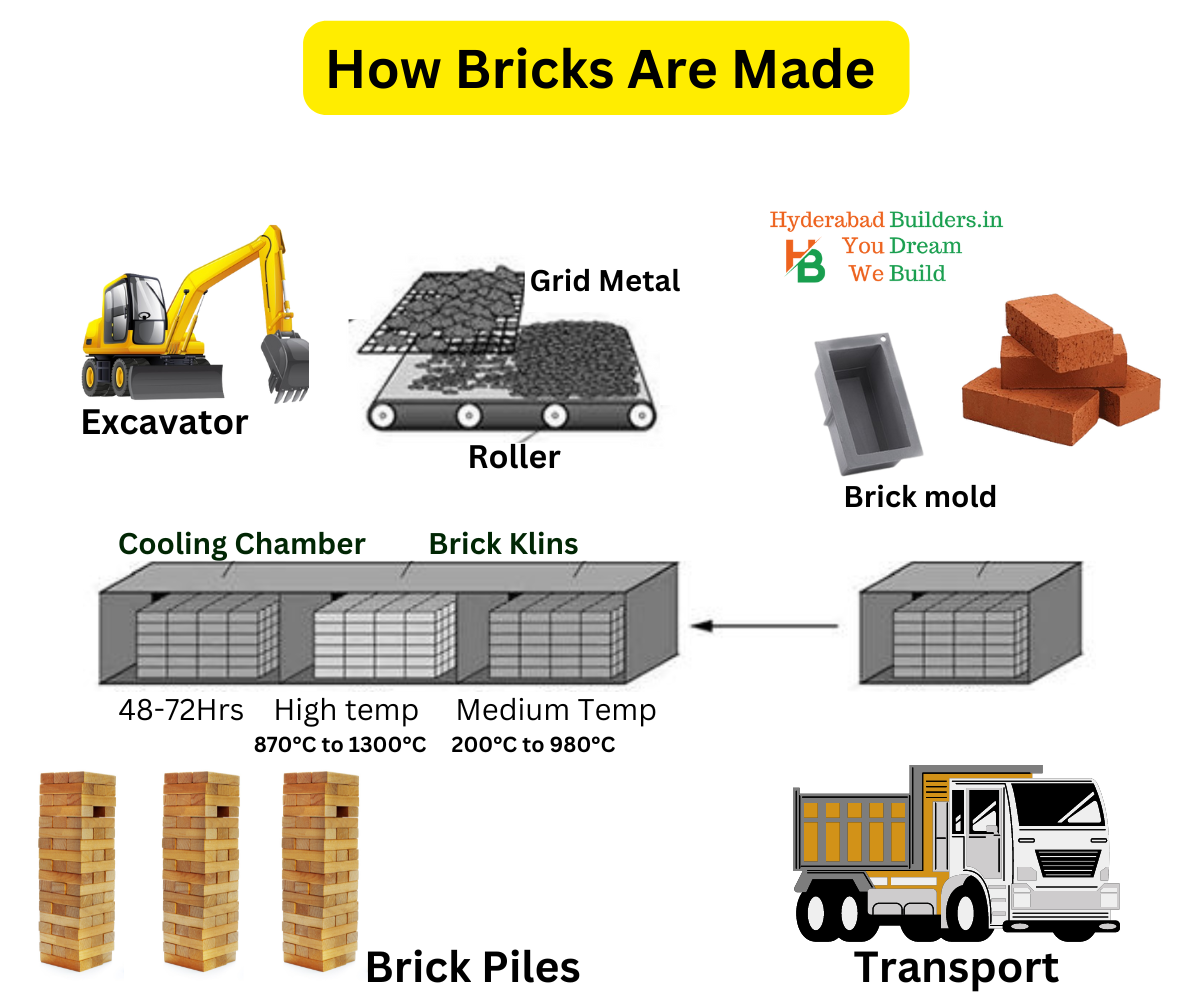

After the mixin’, it’s time to form the bricks.

You got yourself a mold, and you gotta pack that mold tight with your brick mix. If you don’t pack it tight, you might end up with air bubbles inside the brick, and that ain’t good! So you push and shove that mix into the mold, pack it down good, and sometimes even shake it a bit to make sure there ain’t no air pockets. Once it’s packed, you let it sit for a while so it hardens up a bit.

Now, you need to dry them out.

Once the bricks are formed, you can’t just throw ‘em straight into the fire. Oh no, you gotta let ‘em dry out real good first. If you don’t, they could crack or break when you put ’em in the kiln. I usually leave ‘em to dry for a couple of days, dependin’ on the weather. If it’s hot and dry, it don’t take too long. But if it’s rainy or damp, you might have to wait a little longer.

Once they’re dry, it’s time to fire ’em up.

Now, here’s where the real magic happens. You gotta bake them bricks in a high-temperature furnace or kiln. The heat’s what makes them tough and fire-resistant. This process is called “firing,” and it’s crucial to get the bricks to their final, hard state. I usually set the temperature way up—around 1200 to 1500 degrees Fahrenheit, or even higher, dependin’ on the kind of brick I’m makin’. It’s gotta stay in there for hours, sometimes even a whole day, just cookin’ and hardenin’.

After they’re fired, they get inspected.

Once the bricks come outta the kiln, you gotta check ‘em over real careful-like. Make sure there ain’t no cracks or flaws. If a brick’s got a crack, it won’t do you much good in a furnace or a chimney. So, you inspect each one, and if it looks good, you move on to the next step.

Finally, the packaging and delivery.

Once they’re all done and checked, it’s time to pack ‘em up and ship ‘em off. These bricks are heavy, and you don’t wanna drop ‘em, so they gotta be wrapped up tight. Sometimes they’re stacked on pallets or in crates, ready to go to their new home, whether it’s a kiln or a firebox.

- First, get your materials together.

- Mix ’em up right.

- Pack the mold tight to get the right shape.

- Let ‘em dry good before firin’.

- Fire ‘em up in a kiln at high temperatures.

- Inspect ‘em to make sure they’re good to go.

- Finally, pack ‘em up and ship ‘em out!

Different types of firebricks.

Now, not all refractory bricks are the same. Some are made for different jobs. You got your silica bricks, which are great for withstanding high heat. And then there’s chromite bricks, which are made from fireclay and chromium ore. These ones are used in places where there’s a lot of heat and pressure, like in steel mills or furnaces.

In conclusion, making refractory bricks is a tough but necessary job.

Whether you’re buildin’ a furnace for a big ol’ factory or just makin’ a simple chimney, these bricks are essential for keepin’ things runnin’ smoothly. They can handle the heat, the pressure, and all that wear and tear. So next time you see a brick in a kiln or oven, just remember, there’s a whole lotta work that goes into makin’ sure it can take the heat!

Tags:[Refractory Bricks, Fire Bricks, High Temperature Bricks, Brick Production, Fireclay, Kiln Bricks, Heat Resistant Materials, Sodium Silicate, Brick Manufacturing, Chromite Bricks]