Alright, let’s talk about them kiln bricks, you know, the ones they use in them big ol’ ovens. Folks always wonderin’ what they’re made of, so I’m gonna tell ya, plain and simple, like it is.

First off, ya gotta start with dirt, ya know, clay. That’s the main thing, the real heart of it. They dig it up from the ground, sometimes it’s close to the top, sometimes ya gotta dig a bit deeper. This ain’t just any dirt though, it’s special dirt, gotta be the right kind. They call it clay or shale sometimes, fancy names for dirt if ya ask me.

Now, this dirt, it ain’t always enough on its own. Sometimes it needs a little help, ya know, to make it stronger or somethin’. So they might add some sand to it, or maybe some lime. I heard tell they even put in coal powder sometimes, makes it burn better I guess. And some other stuff too, like iron oxide, makes it look reddish, and other things, I don’t even know the names, just stuff they mix in.

- Clay: The main stuff, ya know, the dirt.

- Sand: Makes it strong, I reckon.

- Lime: Another helper, makes it good.

- Coal Powder: Helps with the burnin’.

- Iron Oxide and other stuff: For color and other things.

After they got all the stuff mixed up, they gotta grind it down, make it all fine and even. Can’t have no big chunks in there, that ain’t gonna work. They use big machines for that, crushin’ and grindin’ it all up.

Then comes the makin’ of the bricks themselves. They got machines for that too, squishin’ the dirt mixture into them brick shapes. They ain’t always perfect, ya know, sometimes they a little crooked, but that’s alright, they still work just fine.

Now, the real important part, the burnin’. They gotta cook them bricks in a big ol’ oven, what they call a kiln. These kilns, they get hotter than heck, hotter than anything you ever seen. We’re talkin’ thousands of degrees, makes my head spin just thinkin’ about it.

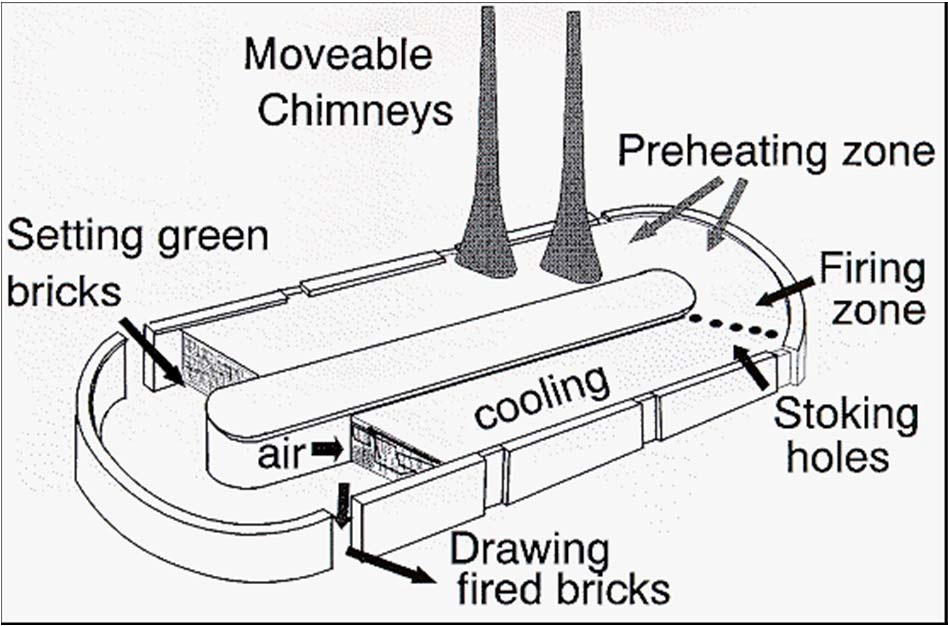

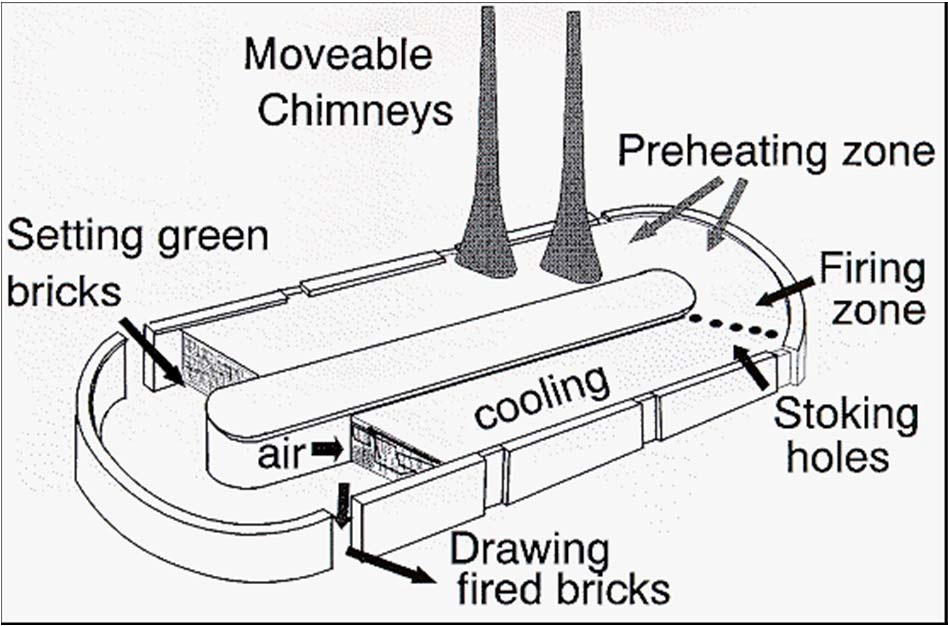

There’s different kinds of kilns, some they just fill up and burn, then let it cool down. Others, they keep burnin’ all the time, they just keep pushin’ the bricks through, like a train going through a tunnel. Them tunnel kilns, they’re somethin’ else, always burnin’, always makin’ bricks.

Inside that kiln, the bricks get hard, real hard. The heat changes ’em, makes ’em strong enough to build with, to stand up to the weather and everything. The fire, it does somethin’ to that dirt, turns it into somethin’ new. They gotta watch it close though, make sure it gets hot enough, but not too hot, gotta be just right.

And that’s pretty much it, that’s how they make them kiln bricks. It’s all about the dirt, the mixin’, the shapin’, and the burnin’. Takes a lot of work, but them bricks, they last a long time, they hold up good. They use them special refractory bricks inside them big ovens, these ain’t just regular bricks mind you, they can take that crazy heat, made with different stuff like alumina and silica, and magnesium and calcium and potassium thingys. They gotta be tough, to stand up to that fire day in and day out.

So next time ya see a brick wall, or a fireplace, or even a pizza oven, ya know a little somethin’ about where them bricks come from and what they’re made of. It ain’t magic, it’s just good ol’ dirt and fire, and a whole lotta hard work.

Tags: [Kiln Bricks, Brick Manufacturing, Refractory Bricks, Clay Bricks, Tunnel Kilns, High Temperature Materials, Brick Production, Kiln Firing, Building Materials, Construction Materials]