Today, I messed around with alumina castable. This stuff is kinda like cement, but way tougher and can handle crazy heat. It’s made from alumina, which I guess is some kind of special material.

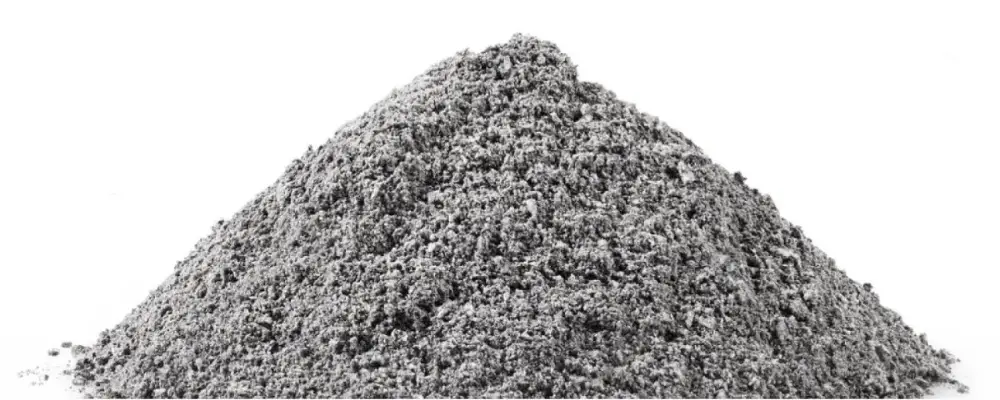

First off, I got my hands on the castable mix. It was this powdery stuff. I followed the instructions from the manufacturer. Can’t stress this enough – always, always do what they say on the packet. It’s like baking a cake, you gotta follow the recipe, or it’s gonna be a disaster.

Mixed it with water next. But not too much! I wanted it to flow just right, not be all watery. Getting the right mix is key, you want it like, kinda like a thick milkshake, I guess? Not too runny, not too stiff.

Then, I poured it into this mold I made. I’m making a, uh, let’s call it a “heat-resistant brick” for now. Just experimenting, you know? I poured it in slowly, tapping the sides to get rid of any air bubbles. Don’t want those in there.

- Waited for it to set. This took a while. Patience is a virtue, they say. Good thing I had other stuff to do.

- Once it was kinda hard, I took it out of the mold. It looked pretty good! Solid, no cracks or anything.

- Now, it needed to cure. That means letting it sit and get even stronger. I left it alone for a day or two, just to be sure.

Finally, I tested it out. I don’t have a furnace or anything, but I did hit it with a blowtorch. Just to see what would happen. It held up! No melting, no cracking, nothing. This stuff is tough!

So, yeah, that was my day with alumina castable. Pretty cool stuff. I can see why they use it in boilers and furnaces and stuff. It’s like, super cement. I’m thinking of what else I can make with it. Maybe a mini forge? We’ll see.

Understand that alumina castable has many different types, and the type can affect the result. I used a common type this time, but I will try other types next time. Choosing the right one is important; otherwise, it’s not going to work.

It’s really a fun experience; if you get a chance to try it out, go for it. Just remember to read those instructions!