Refractory bricks are a crucial component in many industries, providing insulation and protection from high temperatures and harsh environments. These specialized bricks are made from materials that can withstand extreme heat and other challenging conditions, making them essential in industries such as steelmaking, cement manufacturing, and glass production. In this guide, we'll explore the benefits, types, and applications of refractory bricks.

Benefits of Refractory Bricks

The primary benefit of refractory bricks is their ability to withstand high temperatures. They are made from materials that can resist thermal shock, which occurs when materials rapidly expand or contract due to temperature changes. Refractory bricks can also resist abrasion, corrosion, and chemical attack, making them ideal for use in harsh industrial environments.

Refractory bricks also offer excellent insulation properties, which can help to reduce energy costs and improve efficiency. By preventing heat loss, refractory bricks can maintain high temperatures inside furnaces and other equipment, reducing the amount of fuel needed to maintain the desired temperature.

Types of Refractory Bricks

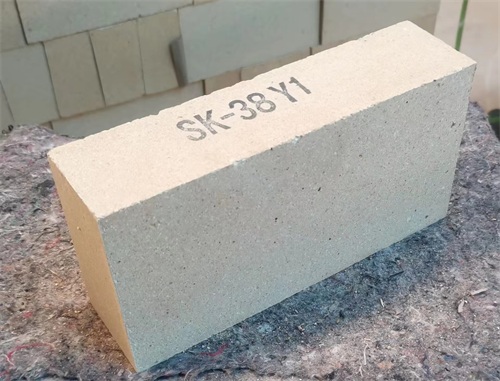

There are several types of refractory bricks, each with its own unique properties and applications. The most common types include:

1.Fireclay bricks: These are made from clay and other materials, and are commonly used in the construction of chimneys, fireplaces, and other residential heating applications.

2.Silica bricks: These are made from silica, a naturally occurring mineral, and are used in high-temperature applications such as glassmaking and steelmaking.

3.Magnesia bricks: These are made from magnesia, a mineral that is highly resistant to heat and corrosion. Magnesia bricks are commonly used in the steel industry, as well as in cement manufacturing and other high-temperature applications.

4.Chrome bricks: These are made from chrome ore, and are highly resistant to corrosion and high temperatures. They are often used in the production of chemicals and in other harsh industrial environments.

Applications of Refractory Bricks

Refractory bricks are used in a wide range of applications, from residential heating systems to large industrial furnaces. Some common applications include:

1.Steelmaking: Refractory bricks are used to line the walls of steelmaking furnaces, protecting them from the high temperatures and corrosive gases produced during the process.

2.Cement manufacturing: Refractory bricks are used to line kilns in cement plants, where they are exposed to high temperatures and abrasive materials.

3.Glass production: Refractory bricks are used to line glass furnaces, where they can withstand the extremely high temperatures needed to melt glass.

4.Residential heating: Fireclay bricks are commonly used in residential heating applications, such as chimneys and fireplaces.

Conclusion

Refractory bricks are a critical component in many industries, providing insulation and protection from high temperatures and harsh environments. They offer several benefits, including the ability to withstand thermal shock, resist abrasion and corrosion, and provide excellent insulation properties. There are several types of refractory bricks available, each with its own unique properties and applications. They are used in a wide range of industries, from steelmaking to glass production to residential heating. Understanding the benefits, types, and applications of refractory bricks is essential for anyone working in these industries.

Contact: Mgr. Han

Phone: 0086-13589497465

Email: 1255953279@qq.com

Add: Industrial Area of Lingzi Town,Zichuan District,Zibo City, Shandong,China