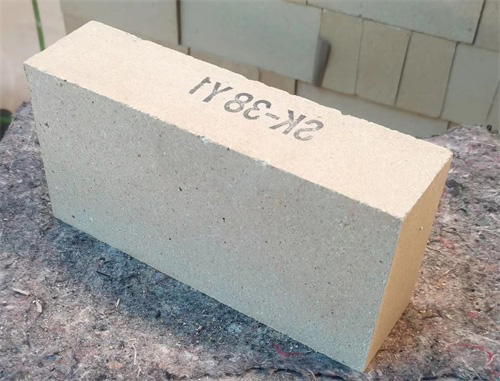

High alumina brick is a specialized type of refractory brick that is designed to withstand high temperatures and harsh environments. It is made from a mixture of high-purity alumina and other materials, such as silica and magnesia, and is known for its exceptional durability and resistance to corrosion and erosion.

The science behind high alumina brick is fascinating, and understanding how it works and why it's superior can help you appreciate the benefits of this unique material.

What is High Alumina Brick?

High alumina brick is a type of refractory brick that contains more than 45% alumina (Al2O3) by weight. It is made from a mixture of high-purity alumina and other materials, such as silica and magnesia. The exact composition of high alumina brick can vary depending on its intended use.

High alumina brick is known for its exceptional resistance to heat, erosion, and corrosion, and is used in a variety of applications, from lining furnaces to building kilns.

How it Works

When high alumina brick is exposed to high temperatures, several physical and chemical processes occur that help it withstand the heat.

One key process is sintering, which is the process of bonding particles together through heat and pressure. When high alumina brick is fired at high temperatures, the alumina particles fuse together, creating a dense, hard material that is resistant to heat and erosion.

Another important process is the formation of mullite. Mullite is a mineral that forms when alumina and silica are heated together at high temperatures. Mullite is highly refractory and has a low thermal expansion coefficient, which makes it an ideal material for use in high-temperature applications.

The unique combination of sintering and mullite formation results in a material that can withstand temperatures of up to 3300°F (1815°C) without degrading.

Why it's Superior

High alumina brick is known for its exceptional durability and resistance to corrosion and erosion, and there are several reasons why it's superior to other types of refractory brick.

Firstly, high alumina brick has a high alumina content, which makes it more resistant to thermal shock than other types of refractory brick. This means that it can withstand rapid changes in temperature without cracking or breaking.

Secondly, high alumina brick is highly resistant to erosion and corrosion. It can withstand exposure to harsh chemicals and abrasive materials without degrading, which makes it ideal for use in environments such as steel mills and chemical plants.

Finally, high alumina brick has a low thermal expansion coefficient. This means that it does not expand or contract significantly when exposed to high temperatures, which helps to prevent cracking and damage to the brick.

Applications of High Alumina Brick

High alumina brick has a wide range of applications, and is used in industries such as steelmaking, glassmaking, and ceramics.

One of the most common applications of high alumina brick is in furnaces and kilns. High alumina brick is used to line the interior of these structures, protecting them from the high temperatures and harsh conditions that are present during the heating process.

High alumina brick is also used in the construction of blast furnaces, which are used to produce iron and steel. Blast furnaces operate at very high temperatures, and high alumina brick is able to withstand the harsh conditions present in these environments.

In addition, high alumina brick is used in the production of glass and ceramics. The high purity of the alumina used in high alumina brick helps to prevent contamination of the final product, which is important in industries where purity is critical.

Conclusion

High alumina brick is a remarkable material that has been used for decades to withstand high temperatures and harsh environments. The unique combination of sintering and mull ite formation results in a material that is highly refractory, durable, and resistant to erosion and corrosion.

Understanding the science behind high alumina brick can help you appreciate the benefits of this unique material. Its exceptional resistance to heat and harsh chemicals makes it an ideal material for use in a wide range of applications, from lining furnaces to building kilns.

As industries continue to demand more durable and energy-efficient materials, high alumina brick is likely to remain a popular choice. Ongoing research and development efforts are focused on improving the properties of high alumina brick, such as increasing its thermal conductivity and reducing its weight.

Overall, the science behind high alumina brick is a testament to the ingenuity of humans to create materials that can withstand extreme conditions. Whether it's producing steel or making glass, high alumina brick is a reliable and durable solution that has stood the test of time.

Contact: Mgr. Han

Phone: 0086-13589497465

Email: 1255953279@qq.com

Add: Industrial Area of Lingzi Town,Zichuan District,Zibo City, Shandong,China