Mullite bricks are a type of refractory brick made of high-purity alumina and silica materials. They are known for their excellent high-temperature resistance, low thermal expansion, and resistance to thermal shock. These properties make them ideal for use in high-temperature applications such as furnaces, kilns, and incinerators. However, selecting the right mullite bricks for your specific application can be a daunting task. In this article, we will provide you with a guide to help you select the right mullite bricks for your specific application.

1.Understand Your Application Requirements

Before selecting mullite bricks for your application, it is essential to understand your application requirements. You need to know the temperature range, pressure, and chemical environment that the bricks will be exposed to. This information will help you to determine the type of mullite bricks you need.

2.Choose the Right Grade

Mullite bricks come in different grades, each with unique properties that make them suitable for specific applications. For instance, high alumina mullite bricks are ideal for high-temperature applications, while low alumina mullite bricks are suitable for low-temperature applications. If your application involves exposure to high pressure, you may want to consider high-density mullite bricks, which are more resistant to mechanical stress. The choice of the grade of mullite brick will depend on your application requirements.

3.Consider the Thermal Conductivity

Thermal conductivity is the measure of a material's ability to conduct heat. In high-temperature applications, it is essential to consider the thermal conductivity of mullite bricks. Bricks with high thermal conductivity will be able to transfer heat more efficiently, while those with low thermal conductivity will retain heat for longer periods. The choice of the thermal conductivity of the mullite brick will depend on your application requirements.

4.Check the Chemical Composition

The chemical composition of mullite bricks can affect their performance in specific applications. For instance, mullite bricks with a high silica content are more resistant to acidic environments, while those with high alumina content are more resistant to alkaline environments. Understanding the chemical environment that your mullite bricks will be exposed to is essential in selecting the right chemical composition.

5.Look for High-Quality Bricks

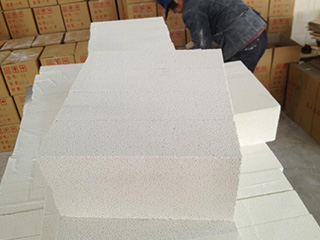

The quality of mullite bricks can vary significantly from one manufacturer to another. It is essential to look for high-quality bricks that are manufactured using high-purity raw materials and advanced production techniques. High-quality mullite bricks will have excellent thermal shock resistance, high-temperature resistance, and low thermal expansion.

6.Consider the Size and Shape

Mullite bricks come in different sizes and shapes, and the choice of size and shape will depend on your application requirements. If your application involves lining large furnaces or kilns, you may need to consider larger bricks, while smaller bricks may be suitable for smaller applications. The shape of the brick can also affect its performance in specific applications. For instance, straight bricks may be suitable for lining straight walls, while curved bricks may be ideal for lining curved walls.

7.Consult with Experts

Selecting the right mullite bricks for your application can be a challenging task, especially if you are not familiar with the properties and characteristics of these bricks. It is advisable to consult with experts in the field of refractory materials. They will be able to advise you on the right type of mullite bricks for your specific application.

Conclusion

Selecting the right mullite bricks for your specific application requires a thorough understanding of your application requirements. You need to consider the temperature range, pressure, and chemical environment that the bricks will be exposed to. You also need to choose the right grade, consider the thermal conductivity, check the chemical composition, look for high-quality bricks, consider the size and shape, and consult with experts in the field. By taking these factors into consideration, you can ensure that you select the right mullite bricks for your specific application, and achieve optimal performance and longevity. It is also important to regularly inspect and maintain your mullite brick lining to ensure that it continues to perform effectively and safely. With proper selection and maintenance, mullite bricks can provide reliable and durable performance in high-temperature applications for many years.

Contact: Mgr. Han

Phone: 0086-13589497465

Email: 1255953279@qq.com

Add: Industrial Area of Lingzi Town,Zichuan District,Zibo City, Shandong,China